The field is required.

KODEST-Sharp Edge Anti Corrosion Superior Coating

2025-04-25

KODEST-Sharp Edge Anti-Corrosion Superior Coating is true next generation and a true game changer of protective coatings in corrosion defence in even the vicious environments. Imagine infrastructure that lasts decades longer at a reducedmaintenance-costs and a reducedenvironmental-impact. The Space Age Coating is designed for the most extreme applications needing unparalleled protection, such as bridges, offshore platforms, pipelines, and industrial equipment. Exceptional Durability

KODEST was formulated in a unique way to make it best in class for abrassive, impact and UV resistance. The polymer matrixit it uses creates a permanent and highly efficient protective layer against corrosive agents while significantly extending the service life of corroded surfaces.

Prototypical testing-Field demonstrated Fisher's break-through was superior to traditional epoxy coatings, showing only minor degradation after long-term serial exposure to seawater, chemicals and temperatures.

More resistant toCorrosion

It means that their coating acts as a barrier from the processes that cause rust, decay, and breakdown (these are all essentially electrochemical processes, after all). With its molecular structure so tightly packed that moisture and oxygen cannot enter, it creates a complete barrier impermeable to thecorrosive elements.

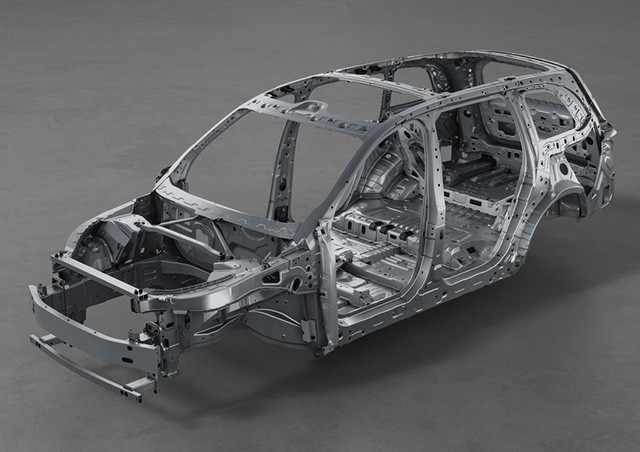

This improved level of barrier protection is greatest on traditional corrosion risk areas, such as weld and sharp edges, so they have named it "Sharp Edge" protection.

Ease of Application

PH:KODEST-Sharp Edge offers the most comprehensive protection, but is designed to be simple in applicationPH:KODEST-Sharp Edge offers the most comprehensive protection, but is designed for easy application Being low-VOC it is environmentally neutral, plus it works with conventional spray equipment, making it efficient and cost-effective across large surfaces.

Dubbed as the fastest-drying sealant from anywhere in its group, thefast-drying traits of the coating minimizes downtime, which helps increase productivity in the project and, thus, a more cost-effective coating.

KODEST was formulated in a unique way to make it best in class for abrassive, impact and UV resistance. The polymer matrixit it uses creates a permanent and highly efficient protective layer against corrosive agents while significantly extending the service life of corroded surfaces.

Prototypical testing-Field demonstrated Fisher's break-through was superior to traditional epoxy coatings, showing only minor degradation after long-term serial exposure to seawater, chemicals and temperatures.

More resistant toCorrosion

It means that their coating acts as a barrier from the processes that cause rust, decay, and breakdown (these are all essentially electrochemical processes, after all). With its molecular structure so tightly packed that moisture and oxygen cannot enter, it creates a complete barrier impermeable to thecorrosive elements.

This improved level of barrier protection is greatest on traditional corrosion risk areas, such as weld and sharp edges, so they have named it "Sharp Edge" protection.

Ease of Application

PH:KODEST-Sharp Edge offers the most comprehensive protection, but is designed to be simple in applicationPH:KODEST-Sharp Edge offers the most comprehensive protection, but is designed for easy application Being low-VOC it is environmentally neutral, plus it works with conventional spray equipment, making it efficient and cost-effective across large surfaces.

Dubbed as the fastest-drying sealant from anywhere in its group, thefast-drying traits of the coating minimizes downtime, which helps increase productivity in the project and, thus, a more cost-effective coating.

SUBSCRIBE

CONTACT US

IF YOU REQUIRE THE MOST SUITABLE PRODUCTS, FEEL FREE TO CONTACT US.

If you have any questions about our products or services, feel free to reach out to customer service team.

INQUIRY