The field is required.

Advanced Cathodic Dip Painting Processes

2025-04-15

However, over the years, we have developed cathodic dip painting processes that have incorporated a major advance in industrial coating. It offers the same advantages of corrosion protection, look, and performance as a standard paint process while improving efficiency. Improve Product Durability For manufacturers looking to improve their product finishing process, it is important to know what goes into the process. In this article, we explore this technology in detail; the fundamentals of it, its advantages, and its applications. Fundamentals of Quality Cathodic Dip Painting

All modern cathodicdip coating is basedon this electrodeposition principle. In this process, a conductive workpiece (typically metal) is submerged ina bath of a dispersion of paint. The negatively paint charged paint particles are attracted to the positively charged workpiece (the cathode) and coats the workpiece uniformly when direct current is applied. The complexity involved here is due to multiple parameters to control such as current density, bath temperature and composition of paint for the optimum thickness, adhesion, etc., and other quality parameters of the coating.

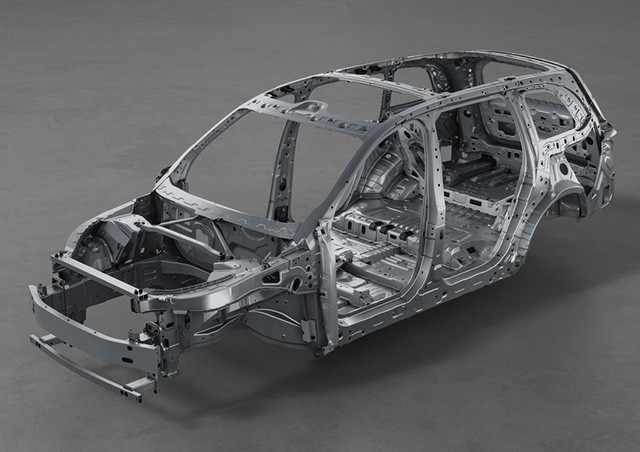

The resulting coating is very uniform through complex geometries if cathodic dip painting is employed, but it is better than conventional methods like spraying or brushing. This means that electrostatic attraction actively drawning the coating in all recesses and nooks and crannies, avoiding an uneven coverage and with it, potential corrosion vulnerabilities especially in complex parts.

That is made possible by improving paints, electrolyte chemistry, and control systems. This stage also allows for improved control over the deposition process (thinner coats and increased durability) as well as a more environmentally sustainable process (more efficient use of paint).

Advantages of New Cathodic Dip Paints Over Old Types

One of the most significant advantages is the excellent corrosionprotection provided by progressive cathodic dip painting. Since it forms a film providing full surface contact (even in cavity areas),it allows for protection against environmental factors such as moisture and salt spray, extend the service life of coated products significantly. This is particularly relevant for automotive components, outdoor tools, and appliances that are used in adverse environments.

Besides the corrosion resistance factor, the process producesa cost effective, small part with a tight tolerance and good, aestheticlooking finish. It features such consistency of the coating surfaceLead to a smooth and uniform texture which is especially ideal for a particular application requiring a perfect appearance. Consequently, additional surface treatments like sand/planning or polishing are not needed, thereby reducing the production time and costs.

One ofthem will be that it will have more advantages than standard ones, because of its relatively large efficiency. Perhaps the most automatic high-throughput process, cathodic dip painting is approachable when mass production is to be concerned. Costs such as material and labor are minimized as less material is wasted during construction and need for labor is also comparatively lower which also adds to its eco friendly quotient!

Furthermore, its use can be widened in respect of coating types with the use of advanced cathodic dipping painting. A ship has an individual need such as durability or UV resistance, or colour to match another object, and this is a specific requirement due to which there are various paint formulations. This flexibility allows manufacturers to tailor the coatingto exactly meet the requirements of the application.

More Advanced Modalities andRefinements

Cathodicdip painting has progressed since the past few years and several recent developments highlight various novel approaches to optimise the process. To prevent the defects, various parameters are measured and monitored which include real-time monitoringand control using advanced sensors and control systems. This level of accuracy is critical in mass production, because it guarantees consistent quality of very large amounts of same product.

These coatings are ineffective without newer paint formulations. These formulations include polymers and additives that are new or improved to promote adhesion, flexibility and durability. The second focus area is creating more sustainable, water-based paints that will help reduce the environmental impact of the process.

Some of the measures involved in process optimization focus on how to avoid errors and optimize the coating process. This includes pre-treatment for proper surface preparation and advanced filtration system to remove contaminates from the paint bath. By addressing these, manufacturers can ensure the final coating is consistent in quality.

Application of Advanced Tech CathodicDip coating

This enhanced-streamlined cathodic dip painting may be appliedfor many different industries. It is used broadly in the automotive industry for car body, bumpers and other part and provides excellent surface finish and corrosion protective. Appliance manufacturers too use this trick to coat washing machines, refrigerators, and other appliances in order to keep them functional and visually appealing too.

Other sectors include building & construction (to coatmetal framing & components), agricultural machinery (to coat tractors & other equipment), and miscellaneous industrial parts manufacturing. Since PVD coating can provide surprisingly high-levels of protection against both wear and tarnish, it is ideal for applications that demand protection but are also complex in shape.

Technology continues to provide new opportunities for use through technological innovation. As the industry pushes harder to develop low carbon, higher performing paints and refine the process to be even more efficient and reproducible, advanced cathodic dip painting will have a larger impact in the future of many different industries.

All modern cathodicdip coating is basedon this electrodeposition principle. In this process, a conductive workpiece (typically metal) is submerged ina bath of a dispersion of paint. The negatively paint charged paint particles are attracted to the positively charged workpiece (the cathode) and coats the workpiece uniformly when direct current is applied. The complexity involved here is due to multiple parameters to control such as current density, bath temperature and composition of paint for the optimum thickness, adhesion, etc., and other quality parameters of the coating.

The resulting coating is very uniform through complex geometries if cathodic dip painting is employed, but it is better than conventional methods like spraying or brushing. This means that electrostatic attraction actively drawning the coating in all recesses and nooks and crannies, avoiding an uneven coverage and with it, potential corrosion vulnerabilities especially in complex parts.

That is made possible by improving paints, electrolyte chemistry, and control systems. This stage also allows for improved control over the deposition process (thinner coats and increased durability) as well as a more environmentally sustainable process (more efficient use of paint).

Advantages of New Cathodic Dip Paints Over Old Types

One of the most significant advantages is the excellent corrosionprotection provided by progressive cathodic dip painting. Since it forms a film providing full surface contact (even in cavity areas),it allows for protection against environmental factors such as moisture and salt spray, extend the service life of coated products significantly. This is particularly relevant for automotive components, outdoor tools, and appliances that are used in adverse environments.

Besides the corrosion resistance factor, the process producesa cost effective, small part with a tight tolerance and good, aestheticlooking finish. It features such consistency of the coating surfaceLead to a smooth and uniform texture which is especially ideal for a particular application requiring a perfect appearance. Consequently, additional surface treatments like sand/planning or polishing are not needed, thereby reducing the production time and costs.

One ofthem will be that it will have more advantages than standard ones, because of its relatively large efficiency. Perhaps the most automatic high-throughput process, cathodic dip painting is approachable when mass production is to be concerned. Costs such as material and labor are minimized as less material is wasted during construction and need for labor is also comparatively lower which also adds to its eco friendly quotient!

Furthermore, its use can be widened in respect of coating types with the use of advanced cathodic dipping painting. A ship has an individual need such as durability or UV resistance, or colour to match another object, and this is a specific requirement due to which there are various paint formulations. This flexibility allows manufacturers to tailor the coatingto exactly meet the requirements of the application.

More Advanced Modalities andRefinements

Cathodicdip painting has progressed since the past few years and several recent developments highlight various novel approaches to optimise the process. To prevent the defects, various parameters are measured and monitored which include real-time monitoringand control using advanced sensors and control systems. This level of accuracy is critical in mass production, because it guarantees consistent quality of very large amounts of same product.

These coatings are ineffective without newer paint formulations. These formulations include polymers and additives that are new or improved to promote adhesion, flexibility and durability. The second focus area is creating more sustainable, water-based paints that will help reduce the environmental impact of the process.

Some of the measures involved in process optimization focus on how to avoid errors and optimize the coating process. This includes pre-treatment for proper surface preparation and advanced filtration system to remove contaminates from the paint bath. By addressing these, manufacturers can ensure the final coating is consistent in quality.

Application of Advanced Tech CathodicDip coating

This enhanced-streamlined cathodic dip painting may be appliedfor many different industries. It is used broadly in the automotive industry for car body, bumpers and other part and provides excellent surface finish and corrosion protective. Appliance manufacturers too use this trick to coat washing machines, refrigerators, and other appliances in order to keep them functional and visually appealing too.

Other sectors include building & construction (to coatmetal framing & components), agricultural machinery (to coat tractors & other equipment), and miscellaneous industrial parts manufacturing. Since PVD coating can provide surprisingly high-levels of protection against both wear and tarnish, it is ideal for applications that demand protection but are also complex in shape.

Technology continues to provide new opportunities for use through technological innovation. As the industry pushes harder to develop low carbon, higher performing paints and refine the process to be even more efficient and reproducible, advanced cathodic dip painting will have a larger impact in the future of many different industries.

SUBSCRIBE

CONTACT US

IF YOU REQUIRE THE MOST SUITABLE PRODUCTS, FEEL FREE TO CONTACT US.

If you have any questions about our products or services, feel free to reach out to customer service team.

INQUIRY