The field is required.

Cathodic Electrophoresis Coating Superior Durability

2025-04-17

The cathodic electrophoresis coating(CED), is one of the most significant and widely used surface treatment technology for high performance coatings. It should be noted that, compared to many traditional methods of painting, this process is both a uniqueblend of efficiency, uniformity and durability-this solution can be found in a variety of applications includingautomotive parts toindustrial equipment. Understanding this jet stream of mass tendency — the science of the phenomenon of CED and the reason for its longevity — makes this phenomenon registered as universal and also the fact that CED will remain, innovatively. The discussion here below will discuss the unique features which make CED coats to perform so well. Steps ofElectrophoretic Deposition

CED has its basis on the concept of electrophoresis This process is used to deposit suspended charged particles – paint pigments dispersed in a liquid medium – onto a conductive substrate using an electric field. In this process, the paint particles (negatively charged in most cases) – when a direct current is applied – migrate to hit the positively charged (the work piece to be coated). Over time these particles begin to deposit at anode and a film of homogeneitys starts to form. It is highly productive, ensuring an even film thickness, even on complex parts and geometries where traditional spraying methods can hardly achieve.

This controlled molding course of not solely improves theefficacy of CED itself, however the coating effectivity as nicely. Parameters likeeg bath temperature, coating voltage, current density can be controlled precisely for the desired effect. This high level precision equates to reduced material waste, increased throughput, and an increased quality end product. Indeed, CED makes it possible to achieve unsurpassed uniformity of coverage via total surfacearea coverage, including hard-to-reach areas.

Uniformity and Better Film Attachment

One of the greater advantages of CED coatings is that these coatings adhere well to the substrate. This more effective adhesion has a number of causes. And first of all, the electrophoretic deposition technique indeed guarantees a strong microscopic interlock between the coating and the substrate. It produces a kind of bond, since The charged particles are literally "drawn" intothe unevenness of the surface of the substrate. Compared to other coating approaches where adhesion rely on either physical or chemical bonding solely,

CED has also amazingadhesion because CED is consist of homogeneus film and constant thickness. A rough finish is a recipe for stress areas, which will crack, peel, or fail well before the expected lifetime of the product. As such the stress points will be minimum and it enables a uniform thickness layer which will help in better bonding between the coating and subject. The uniformity of the paintfilm also allows a comparatively high protection against corrosion and environmental influences, while in less uniform coating processes thin areas can lead to undercut protection.

Enhanced Corrosion Resistance

In particular, CED coatingsfeature more durable corrosion resistance, etc. These canbe due to the uniformity of film thickness, good adhesion and the properties of coating material itself, etc. These CED coatings can keep water, moisture, oxygen, and othercorrosive agents from contacting the coated workpiece, significantly increasing their service life. This is especially important for extreme environments, where conventional coatingsto get worn out only fast.

Due to the nature of the electrophoretic deposition process, corrosion inhibitors can simply be incorporated into the paint formulation. Moreover, these inhibitorsmay also offer an extra protection from environmental assaults to the encapsulated substrate, thereby adding to the overall value of the corrosion inhibition. CED coatings, with both physical barrier and chemical inhibition together,represent one of the best known anti-corrosion options, which make significant improvements in the life of service of coated parts.

Deterring Forceful Stress

CED coatings had also been subject of extensiveresearch not only for corrosion resistance but also for its excelent ability to resist to mechanical stress on the substrate. The reasons for their excellent resistance to chipping, scratching and abrasion lies in their firm adhesion with highplaintext and the uniform film thickness. Their resistance to mechanical damage makes them more suitable for applications where heavy-duty use or other materials come into contact with the glass.

Other CEDcoatings are intrinsically flexible, which in turn enables the coating to be more adept at absorbing mechanical stress. This flexibility allows the coating to accommodate any bending, flexing, or other deformation without cracking or peeling, an important property for applications involving moving parts or dynamic environments. High adhesion level, uniform thickness control, and availability of flexibility are all the factors which made it wearresistance which prolong the substrate life.

Applications and Directions for the Future

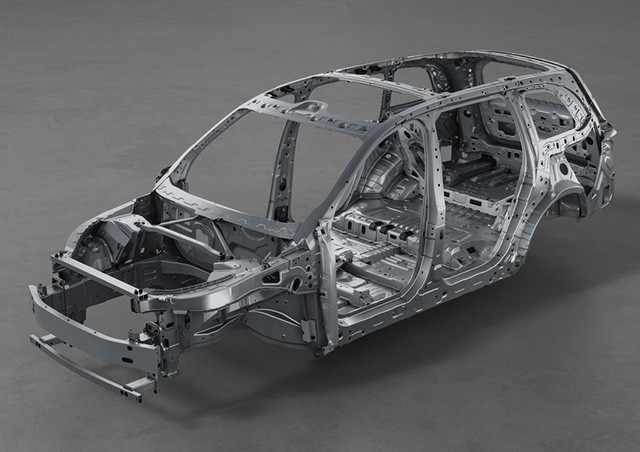

Due to their durability, CED coatings have been utilized in diverse fields. CED is applied in the automotive industry for the thorough protection of carbodies and components as its anti corrosion finish provides a longer life. Similarly, in the appliance industry, CED issupplied to provide a number of durable and aesthetically pleasing finishes onhousehold appliances. Mainly used in industrial sector application, particularly, in heavy machinery and out door equipment, CED offers a wide range of protective properties.

Building on these work horse self-assembly strategies towards more sustainable and eco-friendly CED formulations helps one to characterize new materials and processes to achieve better overall CED efficiency and performance. CED coatings are already robust, but researchers are in the process of developing additional attributes such as self-healing characteristics and enhanced UVresistance. There is still also development to maintain CED as aleading surface treatment technology into the near future.

CED has its basis on the concept of electrophoresis This process is used to deposit suspended charged particles – paint pigments dispersed in a liquid medium – onto a conductive substrate using an electric field. In this process, the paint particles (negatively charged in most cases) – when a direct current is applied – migrate to hit the positively charged (the work piece to be coated). Over time these particles begin to deposit at anode and a film of homogeneitys starts to form. It is highly productive, ensuring an even film thickness, even on complex parts and geometries where traditional spraying methods can hardly achieve.

This controlled molding course of not solely improves theefficacy of CED itself, however the coating effectivity as nicely. Parameters likeeg bath temperature, coating voltage, current density can be controlled precisely for the desired effect. This high level precision equates to reduced material waste, increased throughput, and an increased quality end product. Indeed, CED makes it possible to achieve unsurpassed uniformity of coverage via total surfacearea coverage, including hard-to-reach areas.

Uniformity and Better Film Attachment

One of the greater advantages of CED coatings is that these coatings adhere well to the substrate. This more effective adhesion has a number of causes. And first of all, the electrophoretic deposition technique indeed guarantees a strong microscopic interlock between the coating and the substrate. It produces a kind of bond, since The charged particles are literally "drawn" intothe unevenness of the surface of the substrate. Compared to other coating approaches where adhesion rely on either physical or chemical bonding solely,

CED has also amazingadhesion because CED is consist of homogeneus film and constant thickness. A rough finish is a recipe for stress areas, which will crack, peel, or fail well before the expected lifetime of the product. As such the stress points will be minimum and it enables a uniform thickness layer which will help in better bonding between the coating and subject. The uniformity of the paintfilm also allows a comparatively high protection against corrosion and environmental influences, while in less uniform coating processes thin areas can lead to undercut protection.

Enhanced Corrosion Resistance

In particular, CED coatingsfeature more durable corrosion resistance, etc. These canbe due to the uniformity of film thickness, good adhesion and the properties of coating material itself, etc. These CED coatings can keep water, moisture, oxygen, and othercorrosive agents from contacting the coated workpiece, significantly increasing their service life. This is especially important for extreme environments, where conventional coatingsto get worn out only fast.

Due to the nature of the electrophoretic deposition process, corrosion inhibitors can simply be incorporated into the paint formulation. Moreover, these inhibitorsmay also offer an extra protection from environmental assaults to the encapsulated substrate, thereby adding to the overall value of the corrosion inhibition. CED coatings, with both physical barrier and chemical inhibition together,represent one of the best known anti-corrosion options, which make significant improvements in the life of service of coated parts.

Deterring Forceful Stress

CED coatings had also been subject of extensiveresearch not only for corrosion resistance but also for its excelent ability to resist to mechanical stress on the substrate. The reasons for their excellent resistance to chipping, scratching and abrasion lies in their firm adhesion with highplaintext and the uniform film thickness. Their resistance to mechanical damage makes them more suitable for applications where heavy-duty use or other materials come into contact with the glass.

Other CEDcoatings are intrinsically flexible, which in turn enables the coating to be more adept at absorbing mechanical stress. This flexibility allows the coating to accommodate any bending, flexing, or other deformation without cracking or peeling, an important property for applications involving moving parts or dynamic environments. High adhesion level, uniform thickness control, and availability of flexibility are all the factors which made it wearresistance which prolong the substrate life.

Applications and Directions for the Future

Due to their durability, CED coatings have been utilized in diverse fields. CED is applied in the automotive industry for the thorough protection of carbodies and components as its anti corrosion finish provides a longer life. Similarly, in the appliance industry, CED issupplied to provide a number of durable and aesthetically pleasing finishes onhousehold appliances. Mainly used in industrial sector application, particularly, in heavy machinery and out door equipment, CED offers a wide range of protective properties.

Building on these work horse self-assembly strategies towards more sustainable and eco-friendly CED formulations helps one to characterize new materials and processes to achieve better overall CED efficiency and performance. CED coatings are already robust, but researchers are in the process of developing additional attributes such as self-healing characteristics and enhanced UVresistance. There is still also development to maintain CED as aleading surface treatment technology into the near future.

SUBSCRIBE

CONTACT US

IF YOU REQUIRE THE MOST SUITABLE PRODUCTS, FEEL FREE TO CONTACT US.

If you have any questions about our products or services, feel free to reach out to customer service team.

INQUIRY