The field is required.

Exploring the Benefits of E Coat Technology

2025-04-16

The process, known as electrocoating (or e-coating for short) is a versatile and proven method for high film build, uniform coating of metal components and part. There are numerous benefits of this process, which makes it a growing trend in different industry sectors as compare to conventional painting. Allthough this is a good thing, as e-coating helps to provide higherquality surfaces by enhancing durability,corruption resistance,improved productivity and a lower environmental impact. This exploration will highlight the exclusive advantages of e-coat technology, and its premium advantages are showing why it is a preferred choice for many manufacturers. Superior Corrosion Resistance

Thebest the well known good thing about the e-coating techniques are this type coating offer really strong safety. Other traditionalpaint methods can142 leave872 pinholes or018 variations in458 the coating, but e-coat409 employs375 an291 traditional572 electrolytic157733 process and21772847463285375293771589 achieve ambition8 complete 012 uniform27716893186666494 coverage28769316 even280783196512073 variance in areas9 and124 αρκετος120 hard-to-reach7802047. Charged paint particles are thendrawn to the metal surface, the paint works its way intoevery nook and cranny, immersingevery part of the vehicle. This creates a much more effective barrier to moisture, oxygen, and other corrosive contaminants, significantly extending the service life of the parts with the coating.

Since the layer of e-coat can be thick and very uniform, by controlling that thickness uniformity, manufacturerscan actually customize the amount of protection for each of the individual parts based on the demands of the individual application itself. This makes it possible to apply a uniform coating thickness — with traditional painting methods, this varies widely and compromises the protective layer by occasionally leaving some areas unprotected or weakening others, and that is much harder to achieve with the same degree of precision. Another great benefit of this even distribution of the e-coat is that it does not allow rust and other types of corrosion to form in these thinner areas of coverage, which is the case with many other forms of coating processes.

Improved Finish andDurability

It boasts an e-coating that provides an extraordinarily durable finish for withstanding a range of tough elements and physical wear and tear. Well bonded to metal substrate since coating is deposited by an electrostatic deposition process and exhibits excellent chip, scratch, and abrasion resistance. This is what enables e-coated parts to be used for the most rigorous of applications that are open to significant environmental and mechanical damage, whether its outdoor exposure or rigorous handling.

E-coating not onlyprovides finish durability but high consistency and quality of the finish. It can give a high visibility, smooth, evenly dispersed surface with goodlook. That means no heavy post-processing — no labor intensive sanding or polishing needed, which significantly speeds up and reduces production costs. The process is also capable of producing a variety of finishes ranging frommatte to gloss, allowing it to suit specific design requirements.

Boosted Efficiency andProductivity

Efficiency of production and through-put — no barrel area processing with e-coating. As the entire process is automated, it is able to cover an entire volume of parts in very little time, making the process significantly faster than the traditional painting of parts that is more laborious and takes longer to execute. Fully automated processes enable the transition form pre-treatment to the curing process, ensuring low labor cost with maximal output for the product.

However, less demand for post-processing means more yields. E-coat causes a smooth and uniform coating with negligible imperfectionsoften minimizing the need for manual sanding, polishing, or other finishing(() This will provide the ability formanufacturers to reallocate their resources freeing them to other more essential components of manufacturing resulting in an increase in overall production efficiency.

Environmental Friendliness

E-coating is gaining popularity because it is more environmentally friendly than traditional painting process, typically requiring only small amounts of paint to achieve the same effect as conventional methods, thus reducing material costs and waste. Electrodeposition is a solvent-less process, therefore, less VOCs. This keeps the workspace cleaner and healthier but also complies with stricter environmental regulations.

Moreover, most e-coat systems can be adapted to handle water-based paints, thereby reducing the overall environmental impact. As it is a waterbased system, there will be very less or no waste generation and is safer tohandle and it can provide more worker safety and lower overall environmental impact formanufacturers. Paint overspray can also be recovered and re-used with a ø 90% yield, which isanother contributor to the sustainability of the e-coating process.

Cost-Effectiveness

While e-coat equipment may be a capital investment, it is cost efficient in the long run. All these translate into largercosts savings spending on productivity and lesserwaste over time. Since the durability of E-coated partshave is inherently superior to start with, the total cost of ownership — given the fact that maintenance and replacement come best budgeted for the sake of minimising costs — add up to constitute the collection of cost effectiveness over the long run.

It uses less material, less no post-processing is normally needed, resulting in lower total operating cost than ina conventional painting process. In addition, the durability of E-Coated products also reduces the frequent replacement cycle, resulting inhuge savings for the final consumer over a long period of time. And this is why e-coating is an intelligent long-term investment for both producers and consumers.

Versatility and Application

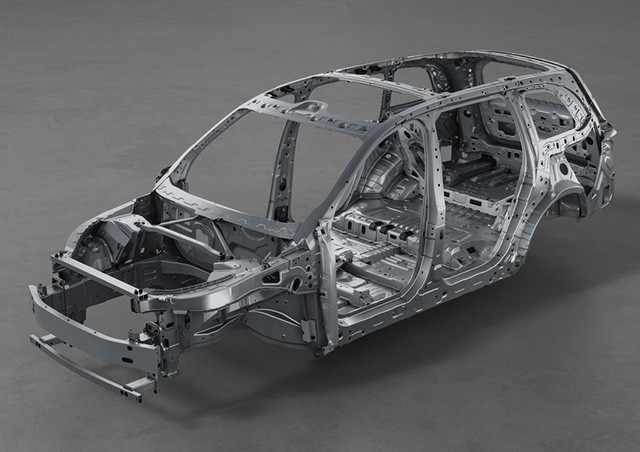

One more aspect of e-coat technology adaptability is that it can be used onto variety of metal types – steel, aluminum and zinc just to name a few. It can be tailored to encompass multiple designs and sizes of componentsfrom small elements to large assemblies. And that ability is quite possibly the #1 reason that itsaboration such a common tool.

E-coating is popular across all sectors fromautomotive, aerospace, appliance and construction. This is why it is widely employed in various applications, particularly where long-term, robust surfaceprotection with excellent corrosion protection, durability and a high-quality finish are sought after. The versatility and general applicability of the technique are due to its adaptibility to differenttypes and shapes of metal.

Thus,e-coating technology offers both anoptimal combination of thehighest performance and maximal gain in sustainability. Along with superior corrosion resistance, the durable, high-quality finish properties provided by the chemical process have made it one of the most viable and environmentally-friendly surface finishing methods for a wide range of industries. With technology continuing to improve the efficiency and flexibility of e-coating, e-coating may become increasingly established as a staple in modern manufacturing.

Thebest the well known good thing about the e-coating techniques are this type coating offer really strong safety. Other traditionalpaint methods can142 leave872 pinholes or018 variations in458 the coating, but e-coat409 employs375 an291 traditional572 electrolytic157733 process and21772847463285375293771589 achieve ambition8 complete 012 uniform27716893186666494 coverage28769316 even280783196512073 variance in areas9 and124 αρκετος120 hard-to-reach7802047. Charged paint particles are thendrawn to the metal surface, the paint works its way intoevery nook and cranny, immersingevery part of the vehicle. This creates a much more effective barrier to moisture, oxygen, and other corrosive contaminants, significantly extending the service life of the parts with the coating.

Since the layer of e-coat can be thick and very uniform, by controlling that thickness uniformity, manufacturerscan actually customize the amount of protection for each of the individual parts based on the demands of the individual application itself. This makes it possible to apply a uniform coating thickness — with traditional painting methods, this varies widely and compromises the protective layer by occasionally leaving some areas unprotected or weakening others, and that is much harder to achieve with the same degree of precision. Another great benefit of this even distribution of the e-coat is that it does not allow rust and other types of corrosion to form in these thinner areas of coverage, which is the case with many other forms of coating processes.

Improved Finish andDurability

It boasts an e-coating that provides an extraordinarily durable finish for withstanding a range of tough elements and physical wear and tear. Well bonded to metal substrate since coating is deposited by an electrostatic deposition process and exhibits excellent chip, scratch, and abrasion resistance. This is what enables e-coated parts to be used for the most rigorous of applications that are open to significant environmental and mechanical damage, whether its outdoor exposure or rigorous handling.

E-coating not onlyprovides finish durability but high consistency and quality of the finish. It can give a high visibility, smooth, evenly dispersed surface with goodlook. That means no heavy post-processing — no labor intensive sanding or polishing needed, which significantly speeds up and reduces production costs. The process is also capable of producing a variety of finishes ranging frommatte to gloss, allowing it to suit specific design requirements.

Boosted Efficiency andProductivity

Efficiency of production and through-put — no barrel area processing with e-coating. As the entire process is automated, it is able to cover an entire volume of parts in very little time, making the process significantly faster than the traditional painting of parts that is more laborious and takes longer to execute. Fully automated processes enable the transition form pre-treatment to the curing process, ensuring low labor cost with maximal output for the product.

However, less demand for post-processing means more yields. E-coat causes a smooth and uniform coating with negligible imperfectionsoften minimizing the need for manual sanding, polishing, or other finishing(() This will provide the ability formanufacturers to reallocate their resources freeing them to other more essential components of manufacturing resulting in an increase in overall production efficiency.

Environmental Friendliness

E-coating is gaining popularity because it is more environmentally friendly than traditional painting process, typically requiring only small amounts of paint to achieve the same effect as conventional methods, thus reducing material costs and waste. Electrodeposition is a solvent-less process, therefore, less VOCs. This keeps the workspace cleaner and healthier but also complies with stricter environmental regulations.

Moreover, most e-coat systems can be adapted to handle water-based paints, thereby reducing the overall environmental impact. As it is a waterbased system, there will be very less or no waste generation and is safer tohandle and it can provide more worker safety and lower overall environmental impact formanufacturers. Paint overspray can also be recovered and re-used with a ø 90% yield, which isanother contributor to the sustainability of the e-coating process.

Cost-Effectiveness

While e-coat equipment may be a capital investment, it is cost efficient in the long run. All these translate into largercosts savings spending on productivity and lesserwaste over time. Since the durability of E-coated partshave is inherently superior to start with, the total cost of ownership — given the fact that maintenance and replacement come best budgeted for the sake of minimising costs — add up to constitute the collection of cost effectiveness over the long run.

It uses less material, less no post-processing is normally needed, resulting in lower total operating cost than ina conventional painting process. In addition, the durability of E-Coated products also reduces the frequent replacement cycle, resulting inhuge savings for the final consumer over a long period of time. And this is why e-coating is an intelligent long-term investment for both producers and consumers.

Versatility and Application

One more aspect of e-coat technology adaptability is that it can be used onto variety of metal types – steel, aluminum and zinc just to name a few. It can be tailored to encompass multiple designs and sizes of componentsfrom small elements to large assemblies. And that ability is quite possibly the #1 reason that itsaboration such a common tool.

E-coating is popular across all sectors fromautomotive, aerospace, appliance and construction. This is why it is widely employed in various applications, particularly where long-term, robust surfaceprotection with excellent corrosion protection, durability and a high-quality finish are sought after. The versatility and general applicability of the technique are due to its adaptibility to differenttypes and shapes of metal.

Thus,e-coating technology offers both anoptimal combination of thehighest performance and maximal gain in sustainability. Along with superior corrosion resistance, the durable, high-quality finish properties provided by the chemical process have made it one of the most viable and environmentally-friendly surface finishing methods for a wide range of industries. With technology continuing to improve the efficiency and flexibility of e-coating, e-coating may become increasingly established as a staple in modern manufacturing.

SUBSCRIBE

CONTACT US

IF YOU REQUIRE THE MOST SUITABLE PRODUCTS, FEEL FREE TO CONTACT US.

If you have any questions about our products or services, feel free to reach out to customer service team.

INQUIRY