The field is required.

High Salt Spray of KODEST ED COATING

2025-04-17

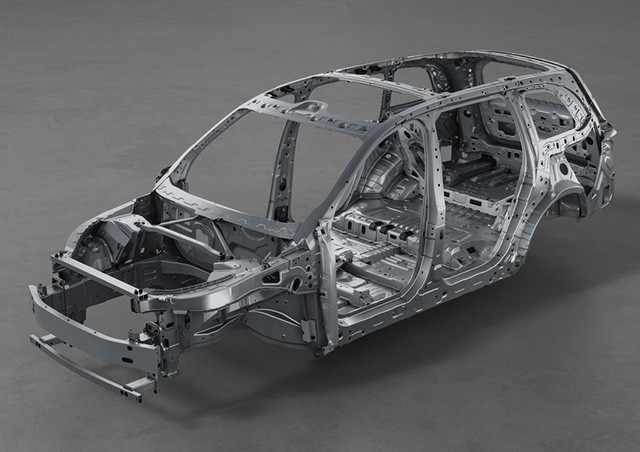

High salt spray test is an important part of the assessment of the corrosion resistance of coatings and KODEST ED coating is significant as a proof of a strong and durable finishing. By far, the most popular application of this coating is on vehicles, and understanding its performance in high salt spray conditions is key to understanding why this is the case. On KODEST ED coating performance at high salt spray, this article describes the finding. Out of This World Corrosive Resistance

Under long term extreme salt spray situations, the KODEST ED coating will resist rust well. The formulation and its application contribute to this superior performance as the coating is uniform, dense, and has almost zero porosity. The coating performs as a neutral barrier that blocks corrosive salt solutions and moisture from entering and forming rust.

KODEST ED coating has shown outperforming independent test results, offering several times longer protection than industry standards for salt spray resistance. This longevity of WearCoat directly relates to longer life of the substrate underneath, avoiding long term time and costs associated with repair.

Uniform Coating and Adhesion

The KODEST ED coating provides consistent quality and uniform deposition, a necessary condition for optimum corrosion protection. This uneven coating results in points of weakness where salt spray can simply work its way through and rust begins ocorrência. The application process of KODEST is much more precise which reduces these vulnerabilities.

The KODEST ED coating also exhibits strong adhesion to wide range of substrates such as steel and aluminum which is also very important to prevent delamination under stress such as the stress induced by salt spray test. This allows the coating to maintain for an extended period and protect the underlying surface thoroughly.

Cost-Effectiveness

KODEST ED coating is a cost-effective solution as despite a marginally higher investment than some alternatives, the vast increase in usefulness and level of corrosion protection achieved more than pay off the initial investment. Less frequent recoating and replacement means long-term maintenance ends up costing significantly less, resulting in a positive ROI.

Additionally, businesses from all industries benefit from reduced idle time and lower replacement costs due to the longer life of parts treated with KODEST ED coating, therefore making it an economical option.

Under long term extreme salt spray situations, the KODEST ED coating will resist rust well. The formulation and its application contribute to this superior performance as the coating is uniform, dense, and has almost zero porosity. The coating performs as a neutral barrier that blocks corrosive salt solutions and moisture from entering and forming rust.

KODEST ED coating has shown outperforming independent test results, offering several times longer protection than industry standards for salt spray resistance. This longevity of WearCoat directly relates to longer life of the substrate underneath, avoiding long term time and costs associated with repair.

Uniform Coating and Adhesion

The KODEST ED coating provides consistent quality and uniform deposition, a necessary condition for optimum corrosion protection. This uneven coating results in points of weakness where salt spray can simply work its way through and rust begins ocorrência. The application process of KODEST is much more precise which reduces these vulnerabilities.

The KODEST ED coating also exhibits strong adhesion to wide range of substrates such as steel and aluminum which is also very important to prevent delamination under stress such as the stress induced by salt spray test. This allows the coating to maintain for an extended period and protect the underlying surface thoroughly.

Cost-Effectiveness

KODEST ED coating is a cost-effective solution as despite a marginally higher investment than some alternatives, the vast increase in usefulness and level of corrosion protection achieved more than pay off the initial investment. Less frequent recoating and replacement means long-term maintenance ends up costing significantly less, resulting in a positive ROI.

Additionally, businesses from all industries benefit from reduced idle time and lower replacement costs due to the longer life of parts treated with KODEST ED coating, therefore making it an economical option.

SUBSCRIBE

CONTACT US

IF YOU REQUIRE THE MOST SUITABLE PRODUCTS, FEEL FREE TO CONTACT US.

If you have any questions about our products or services, feel free to reach out to customer service team.

INQUIRY