The field is required.

Kodest Electrophoretic Coating High permeability

2025-04-15

And that surface finishing process, Kodest Electrophoretic Coating, is even better since it has a high-permeability version. While traditional electrophoretic deposition (EPD) coatings are promising for low coating thickness and normal protective properties, achieving high permeability and still maintain strong protective properties is difficult to achieve with pure EPD coatings. This solution overcomes that limitation and offers a pathway for applications that can benefit from high barrier protection and designed porosity. For industries looking for better treatments to their surface, recognizing its incredible characteristics is the way to go. Higher Permeability for Specific Applications

This Kodest coating is achieved with high permeability by a well-defined manipulation of the pore size and pore distribution within the layer deposited. This imparts selective permeability, thus allowing the passage of selective substrates and at the same time, efficiently blocking others. This is especially advantageous for applications that need releasing substances with some control (e.g. biomaterial or sensors).

Specifically, the pore size and coating thickness can be adjusted to control the release of the drug in the drug delivery system. This could pave the way to more effective and selective drug therapies.

Better Protective Features

The Kodest coating has high permeability and maintains its protective properties. It protects the substrate from corrosion and abrasion and degradation due to environmental conditions. It is this characteristic of permeability together with protection that sets it apart from conventional coatings.

The structural integrity of the coating helps in high durability and low maintenance costs and high life for the coated part. This makes it suitable for usage in tough conditions, where protection and regulated permeability are essential.

Broad Scope of Potential Application Sectors

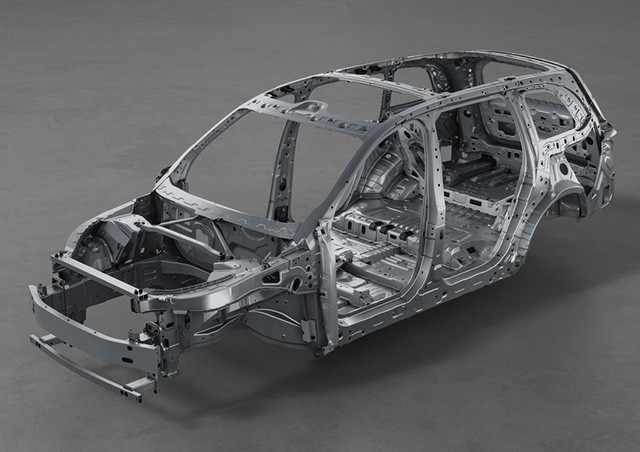

Kodest Electrophoretic Coating High Permeability offers a diverse application scope for multiple industries. It is used for everything from automotive components and aerospace parts (where freedom from corrosion is critical) to biomedical implants (where controlled release is required).

New applications are forever being sought, demonstrating the promise of this innovative surface treatment technology to replace traditional techniques in almost sectors. Additionally, the coating process is flexible and can be easily modified for various substrate compositions and geometries.

This Kodest coating is achieved with high permeability by a well-defined manipulation of the pore size and pore distribution within the layer deposited. This imparts selective permeability, thus allowing the passage of selective substrates and at the same time, efficiently blocking others. This is especially advantageous for applications that need releasing substances with some control (e.g. biomaterial or sensors).

Specifically, the pore size and coating thickness can be adjusted to control the release of the drug in the drug delivery system. This could pave the way to more effective and selective drug therapies.

Better Protective Features

The Kodest coating has high permeability and maintains its protective properties. It protects the substrate from corrosion and abrasion and degradation due to environmental conditions. It is this characteristic of permeability together with protection that sets it apart from conventional coatings.

The structural integrity of the coating helps in high durability and low maintenance costs and high life for the coated part. This makes it suitable for usage in tough conditions, where protection and regulated permeability are essential.

Broad Scope of Potential Application Sectors

Kodest Electrophoretic Coating High Permeability offers a diverse application scope for multiple industries. It is used for everything from automotive components and aerospace parts (where freedom from corrosion is critical) to biomedical implants (where controlled release is required).

New applications are forever being sought, demonstrating the promise of this innovative surface treatment technology to replace traditional techniques in almost sectors. Additionally, the coating process is flexible and can be easily modified for various substrate compositions and geometries.

SUBSCRIBE

CONTACT US

IF YOU REQUIRE THE MOST SUITABLE PRODUCTS, FEEL FREE TO CONTACT US.

If you have any questions about our products or services, feel free to reach out to customer service team.

INQUIRY