The field is required.

Kodest Electrophoretic Coating Superior Paint Protection

2025-04-14

Keeping your car paint safe is a significant part of ensuring your vehicle retains its value and looks its best. While this is visually appealing, the basic paint jobs do not have the high-level of protective technologies. Introducing the Kodest Electrophoretic Coating, a paint protection system that exceeds what traditional systems can achieve. Offering unrivaled strength and corrosion resistance greater than that of normal paint, this new-age technology is an incredible upgrade in vehicle protection. Indeed, this series of articles explains the various benefits of Kodest Electrophoretic Coating with our application process, durability and enhanced paint protection. What Happens Under the Electrophoretic Coating

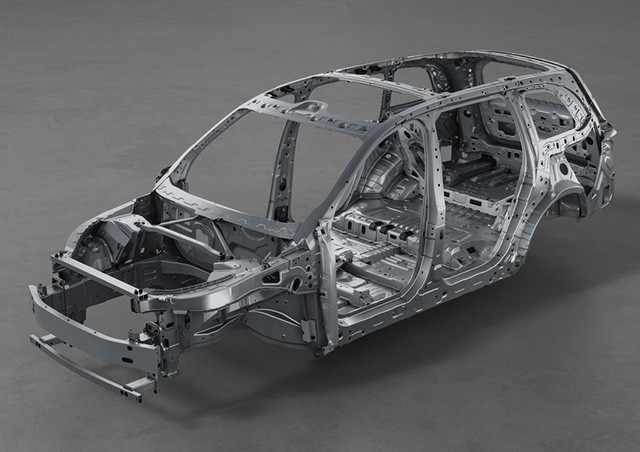

Commonly referred to as E-coat, Kodest Electrophoretic Coating is an electrochemical process by which a thin, uniform layer of paint is deposited onto a substrate, most often the bare metal of a vehicle's chassis or body panels. E-coating differs from traditional spray painting that works by the mechanical adhesion of paint particles. Since the workpiece is also electrically charged — with the opposite pole — the paint particles are drawn to it, producing a perfect and even coat, even where the paint cannot reach. This treament crate assures thus providing a life-long protection against enivornamental number of factors and corrsion beyr it with an adhesion and penetration into thare crevices and seams.

Each application is controlled so that a consistent quality finish is guaranteed. It is this consistency that is necessary for obtaining the best protection, without weak points that will be able to break the integrity of coating. It seems small, but a thin molecular layer provides remarkable coverage and gets into microscopic crevices in the metal surface, making it an impenetrable boundary to the elements. The evenly applied material reduces the risk of pinholes or uneven application commonly associated with traditional spray painting, thus resulting in improved longevity and performance.

Ultimate Protection against Corrosion

Initial experts point to one of the largest benefits of Kodest Electrophoretic Coating is its corrosion resistance. Since the paint was deposited electrically, it is a continuous, very tightly bonded layer, which will keep moisture and oxygen away from the metallic surface underneath. It provides a near-impenetrable shield that helps to mitigate rust and other corrosion, prolonging the life of the sheet metal and structural components of the vehicle. This is a lot more significant in extreme environments where high humidity, salt spray, or other corrosive agents are common.

The better adhesion of E-coating also adds to its higher corrosion resistance. In contrast with traditional paint, which chips or peels and exposes the metal, the E-coating sticks to the metal even when pushed hard. It bonds tightly enough that even if the outer paint layers become scratched or damaged, they remain protected. This in turn means longer vehicle life and fewer bills for rust repair and replacement.

Improved Durability and Lifespan

In addition to high corrosion protection, Kodest Electrophoretic Coating has high durability. This uniform layer protects against chipping, cracking and peeling in ways that conventional paint systems cannot. This longer-lasting protection is due to the formation of a mechanical and chemical bond between the paint and the substrate during the electrochemical bonding process.

The permanence of Kodest Electrophoretic Coating also means that you save money in the long term. This helps to significantly cut maintenance costs since it minimizes the frequency for repainting or touch-ups. This sturdiness comes especially handy for applications that involve a vehicle used under strenuous conditions, temperate areas, or extreme operational scenarios. You will recoup this initial investment with a longer-lasting vehicle, after all WEE-2 is more corrosion resistant, therefore less will go into the repair shop.

Environmental Benefits

Kodest Electrophoretic Coating is also a very environmentally friendly process. The process itself is more efficient than spray painting, generating less paint waste and emitting less volatile organic compounds (VOCs). This leads to cleaner and healthier manufacturing within the context of sustainable manufacturing practices.

Additionally, E-coating improves corrosion resistance, resulting in an even lower requirement for repairs or replacement of damaged equipment and components, reducing its effects on the environment. A longer lifespan for cars that have been coated with E-coating means less overall vehicle production and disposal and creates a more sustainable car industry.

Conclusion

Kodest Electrophoretic Coating is Coating for Paint Protection The corrosion resistance, durability, and environmentally-friendly method of application all make it an attractive option for vehicle owners looking for protection that lasts. When you invest in this premium-grade paint protection system, you are investing not only in the visual appearance of your car but in the fundamentals of your cars build and lifespan, making a sound investment for the value now and in the future.

Commonly referred to as E-coat, Kodest Electrophoretic Coating is an electrochemical process by which a thin, uniform layer of paint is deposited onto a substrate, most often the bare metal of a vehicle's chassis or body panels. E-coating differs from traditional spray painting that works by the mechanical adhesion of paint particles. Since the workpiece is also electrically charged — with the opposite pole — the paint particles are drawn to it, producing a perfect and even coat, even where the paint cannot reach. This treament crate assures thus providing a life-long protection against enivornamental number of factors and corrsion beyr it with an adhesion and penetration into thare crevices and seams.

Each application is controlled so that a consistent quality finish is guaranteed. It is this consistency that is necessary for obtaining the best protection, without weak points that will be able to break the integrity of coating. It seems small, but a thin molecular layer provides remarkable coverage and gets into microscopic crevices in the metal surface, making it an impenetrable boundary to the elements. The evenly applied material reduces the risk of pinholes or uneven application commonly associated with traditional spray painting, thus resulting in improved longevity and performance.

Ultimate Protection against Corrosion

Initial experts point to one of the largest benefits of Kodest Electrophoretic Coating is its corrosion resistance. Since the paint was deposited electrically, it is a continuous, very tightly bonded layer, which will keep moisture and oxygen away from the metallic surface underneath. It provides a near-impenetrable shield that helps to mitigate rust and other corrosion, prolonging the life of the sheet metal and structural components of the vehicle. This is a lot more significant in extreme environments where high humidity, salt spray, or other corrosive agents are common.

The better adhesion of E-coating also adds to its higher corrosion resistance. In contrast with traditional paint, which chips or peels and exposes the metal, the E-coating sticks to the metal even when pushed hard. It bonds tightly enough that even if the outer paint layers become scratched or damaged, they remain protected. This in turn means longer vehicle life and fewer bills for rust repair and replacement.

Improved Durability and Lifespan

In addition to high corrosion protection, Kodest Electrophoretic Coating has high durability. This uniform layer protects against chipping, cracking and peeling in ways that conventional paint systems cannot. This longer-lasting protection is due to the formation of a mechanical and chemical bond between the paint and the substrate during the electrochemical bonding process.

The permanence of Kodest Electrophoretic Coating also means that you save money in the long term. This helps to significantly cut maintenance costs since it minimizes the frequency for repainting or touch-ups. This sturdiness comes especially handy for applications that involve a vehicle used under strenuous conditions, temperate areas, or extreme operational scenarios. You will recoup this initial investment with a longer-lasting vehicle, after all WEE-2 is more corrosion resistant, therefore less will go into the repair shop.

Environmental Benefits

Kodest Electrophoretic Coating is also a very environmentally friendly process. The process itself is more efficient than spray painting, generating less paint waste and emitting less volatile organic compounds (VOCs). This leads to cleaner and healthier manufacturing within the context of sustainable manufacturing practices.

Additionally, E-coating improves corrosion resistance, resulting in an even lower requirement for repairs or replacement of damaged equipment and components, reducing its effects on the environment. A longer lifespan for cars that have been coated with E-coating means less overall vehicle production and disposal and creates a more sustainable car industry.

Conclusion

Kodest Electrophoretic Coating is Coating for Paint Protection The corrosion resistance, durability, and environmentally-friendly method of application all make it an attractive option for vehicle owners looking for protection that lasts. When you invest in this premium-grade paint protection system, you are investing not only in the visual appearance of your car but in the fundamentals of your cars build and lifespan, making a sound investment for the value now and in the future.

SUBSCRIBE

CONTACT US

IF YOU REQUIRE THE MOST SUITABLE PRODUCTS, FEEL FREE TO CONTACT US.

If you have any questions about our products or services, feel free to reach out to customer service team.

INQUIRY