Kodest Electrophoretic Coating Superior Paint Technology

Exceptional Corrosion Resistance

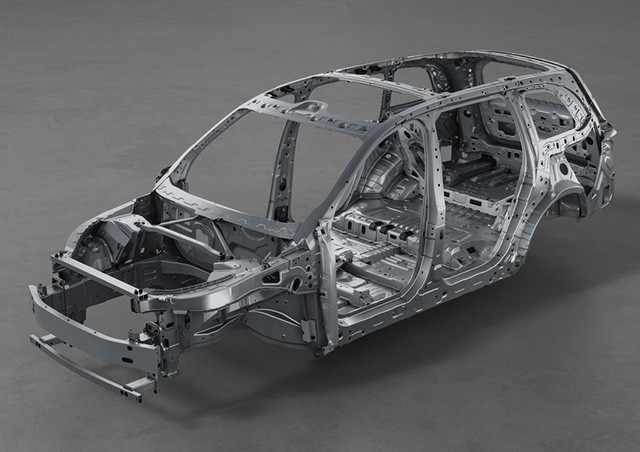

Electrophoretic deposition ensures complete and even coating, reaching into intricate crevices inaccessible to conventional spraying. This comprehensive coverage dramatically enhances resistance to corrosion, crucial for components exposed to harsh environments. The resulting film is exceptionally robust, providing long-term protection against rust and degradation.

The uniform thickness minimizes pinholes and defects, common vulnerabilities in other coating methods, further bolstering the barrier against corrosive agents. This superior protection translates to extended product lifespan and reduced maintenance costs.

Enhanced Surface Quality

Kodest's process delivers a flawlessly smooth and consistent surface finish. The uniform paint layer eliminates imperfections and creates a visually appealing, high-quality aesthetic. This uniformity is unmatched by many traditional painting techniques.

The improved surface finish also allows for easier cleaning and maintenance, further contributing to the overall value and longevity of the coated product. This leads to enhanced product appeal and consumer satisfaction.

Environmental Benefits

Compared to traditional spray painting, electrophoretic coating significantly reduces paint waste and volatile organic compound (VOC) emissions. This environmentally friendly approach aligns with sustainable manufacturing practices.

The precise deposition process minimizes overspray and reduces the need for extensive cleaning, contributing to a cleaner and more efficient manufacturing process, both economically and ecologically beneficial.

SUBSCRIBE

IF YOU REQUIRE THE MOST SUITABLE PRODUCTS, FEEL FREE TO CONTACT US.

INQUIRY