The field is required.

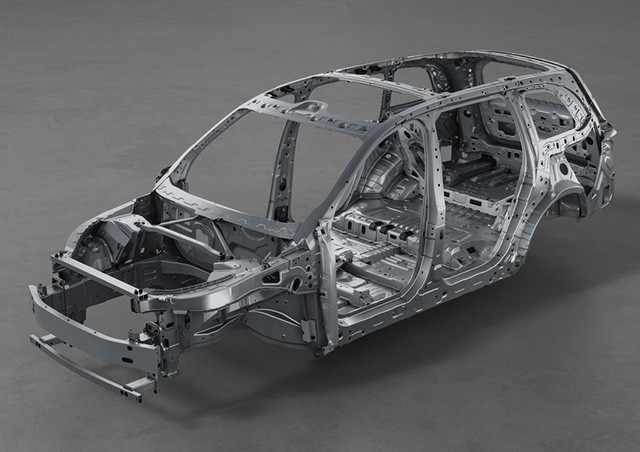

the influence of product material and structure on coating

2025-05-19

According to relevant information, the coating thickness is generally more than three times the surface roughness value of the product material in order to achieve good corrosion resistance.

For example:

The salt spray corrosion resistance of the 40 µ m thick low-temperature baked water-based chassis paint film can reach over 300 hours on phosphated cold-rolled plates, over 240 hours on hot-rolled plates, and only about 150 hours on cast iron plates.

The salt spray corrosion resistance of 20 µ m thick cathodic electrophoretic paint can reach over 1000 hours on phosphated cold-rolled plates, over 800 hours on acid washed and rust removed hot-rolled plates, and only about 600 hours on shot blasted and rust removed hot-rolled plates.

SUBSCRIBE

CONTACT US

IF YOU REQUIRE THE MOST SUITABLE PRODUCTS, FEEL FREE TO CONTACT US.

If you have any questions about our products or services, feel free to reach out to customer service team.

INQUIRY